A new 65′ Catamaran was in South Florida for the installation of a brand new set of Volvo v-driven engines. Unfortunately, after the installation the owner was not happy with the vibration levels and we got a call to come take a look. Since the vessel was in the water we could only go through an engine room inspection. There are very few places in S. Florida to haul a 65′ Cat with 33′ beam and a mast over 100′ so inspecting under the waterline would have to wait for another time.

It did not take long to spot one glaring problem. The latest version of the 150 hp Volvo engine had a change in the steel bracketing system for the heat exchanger. The new bracket was bottomed out and physically touching the base of engine mount. You could see the initial signs of wear in the paint and steel after only a few days of cruising. The exact same problem appeared on both engines.

Any time there is a hard connection between the engine and the vessel the vibration isolation properties of the engine mount are bypassed and the mount cannot do its job. Engine and running gear vibrations are transmitted directly into the vessel.

We removed the mount on each engine for machining modification. Fortunately, we were able to remove the single mount while the engine remained in place. Our machine shop, Straight Line Marine milled a simple relief in the mount base – this was easier than disassembling the motor to modify the bracket. Mount re-installation and an engine alignment was finished in a day and a sea-trial (inter-coastal waterway trial) was immediately conducted. Mystery solved……vibration cured…..customer very happy.

A customer called us last week with a frustrating and persisting vibration problem with his 50′ Sunseeker. The customer is a new owner and does not have a history with the vessel. The vibration was described by the Captain as a “shimmy of the hips”. We did a quick check in the engine room and found one engine running out 0.014″ behind the coupler – this is a dangerous level of run-out which is vibrating the vessel and could cause damage to the transmission if not repaired.

A customer called us last week with a frustrating and persisting vibration problem with his 50′ Sunseeker. The customer is a new owner and does not have a history with the vessel. The vibration was described by the Captain as a “shimmy of the hips”. We did a quick check in the engine room and found one engine running out 0.014″ behind the coupler – this is a dangerous level of run-out which is vibrating the vessel and could cause damage to the transmission if not repaired.

Here is the strange part of the discussion – the owner had a mechanic perform a simple in-water engine alignment and the vibration went away. However, a few weeks later it suddenly came back. This is a very strange symptom that could not be explained until we removed the running gear for a full investigation.

During dis-assembly the couplers were unusually hard to remove. Once removed the damage was apparent. Both coupler keys had been damaged. The coupler on the problematic side was completely sheared and there are clear signs of galling due to the shaft spinning inside the coupler. This is a catastrophic level of damage.

I don’t have a theory on the key failure (shafts were only slightly bent, struts were in alignment so no apparent signs of a hard grounding). However, with the visible galling and shaft spinning it is obvious that the coupler was not seated squarely on the shaft and the mechanic aligned the motor to a “cocked” coupler. Most likely, during a hard run some weeks later, the shaft slipped in the coupler again and caused it to be cocked in another direction – hence the mysterious and sudden return of the vibration.

No big deal in terms of a High Seas repair. The shafts were straightened, keyways repaired, couplers lapped to remove galling and new keys were made in our machine shop. The alignment of the struts were checked and an engine alignment performed with our optical scope alignment system. Once complete the run-out behind the engine was back to an acceptable 0.002″

Another successful sea trial with the Captain; all was very smooth. Mystery solved and another happy customer added to our reference list.

Wartsila Seals are commonly found on larger “class” (ABS, Lloyds,…) vessels. Wartsila seals rely on the proper compression to hold the two faces together. Wartsila designed a specific “tool” that bolts onto the seal flange in four places and compresses the stationary half to the right dimension while remaining perfectly square to the shaft. If the seal is not compressed properly it will leak. With the tools holding the seal in the right location it is simple to move the rotating half into position.

Wartsila Seals are commonly found on larger “class” (ABS, Lloyds,…) vessels. Wartsila seals rely on the proper compression to hold the two faces together. Wartsila designed a specific “tool” that bolts onto the seal flange in four places and compresses the stationary half to the right dimension while remaining perfectly square to the shaft. If the seal is not compressed properly it will leak. With the tools holding the seal in the right location it is simple to move the rotating half into position.

The tool comes with each of the Wartsila seals and needs to be kept on the boat in a safe location. The seals only require adjusting after the shafts have been moved during a haul out and running gear job. As such, the tool is only needed once every few years. As you can imagine, that makes it difficult to find when it is needed.

If you have a vessel with a Wartsila Seal look now for the tool. If you do not have one contact Wartsila or send me an email and I will coordinate getting one shipped out to you.

We always appreciate the opportunity to go on a sea-trial prior to starting any running gear work. A preliminary sea-trial gives us the chance to see and feel the vibration first hand which allows us to start the diagnosis and also compare the before and after.

That was the case with a recent 120′ Intermarine that had a vibration problem. During the sea trial is was apparent that the shafts and props needed significant work. There are many different vibrations that can be felt and heard: shaft hopping, propeller distortion and cavitation are just a few sources. With this vessel we could feel the shaft hop and see the Tides Seal movement in the engine room – a clear sign of bent shafts and a misalignment.

Some vibrations are subtle and some are very bad. This one ranks in the very bad category. The video was taken during the sea trial. We were about 2 miles off Fort Lauderdale in FLAT CALM SEAS. Once the Captain pushed up to 1800 RPMs the vibration was obvious. Everything in the aft cockpit was shaking and moving. There is no way someone could sit around the tables in the aft deck during a cruise. A water bottle placed on the table shook and would walk off the table within 10 seconds.

The vessel was hauled and we are starting the disassembly process. Stay tuned for updates on this vessel in future posts.

Jim Cornell is the founder of Cornell Balancing and truly the best in the business when it comes to analyzing vibrations. No one can beat his experience – analyzing vibrations since 1963! Using a combination of sophisticated equipment and 47 years of ‘feel’ Jim can sort through complex vibrations to find the source. Vibration on a vessel can come from many sources; running gear (shafts or props), engine mounts, exhaust, generators, trim tabs, stabilizers or a structural problem is just the short list.

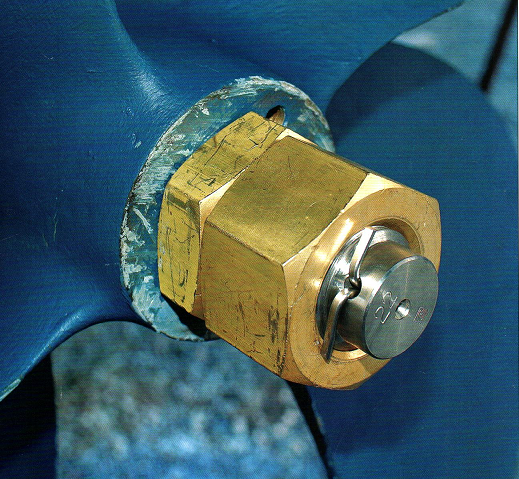

There is one debate in the yard that seams to never end. “Big Nut – Little Nut”, just say those four words to a surveyor and you will get an immediate smile. Does this photo look right to you?

There is one debate in the yard that seams to never end. “Big Nut – Little Nut”, just say those four words to a surveyor and you will get an immediate smile. Does this photo look right to you?

Stay tuned for an upcoming post that provides more insite on this topic. The attached photo is credited to Professional Boatbuilder Magazine and I am working with them to publish past articles on the subject.

In the meantime, feel free to comment on this picture – let the debate begin……again.

We recently got a call from a 90′ Johnson that just finished the seasonal migration from Newport to Fort Lauderdale. The Captain reported a starboard side vibration that was clearly visible in the engine room as a shaft “wobble” while underway.

In a prior post “Electrolysis Destroys a Shaft” we cover a story about a 50′ sailboat that almost lost their Maxprop due to a severely damaged shaft. They were very lucky to haul for routine bottom paint when they did – a few more months and the prop would be gone.

“The entry on shaft electrolysis caught my attention. Electrolysis is a word the marine corrosion community frowns upon, primarily because it references a chemical reaction rather than carrion per se. The photo of the damaged shaft is likely a result of stray current corrosion rarer than galvanic corrosion, which anodes would prevent. No amount of anodic (zinc or otherwise) protection will contend with stray current corrosion for anything more than a short time. Stray current corrosion results from DC current leaking into bilge water or via an un-bonded through hull. It typically causes significant damage in a very short period of time, as opposed to galvanic corrosion, this is the kind that is mitigated by anodes, which occurs slowly. Both are easily identified using a multi-meter, although not always easy to resolve. “

Sincerely,

Steve D’Antonio

Steve D’Antonio Marine Consulting, Inc.

www.stevedmarineconsulting.com/

I will gladly take feedback anytime from a known expert and update the site in an effort to be accurate and educational. Thanks Steve!

Centa flexible couplings are found on larger vessles that have remote transmissions installed and aligned seperately from the main engines. This particular vessel, a 130′ Alloy, was hauled out for an extensive dry-dock period. The props had suffered some grounding damage and it was time for a running gear check.

A typical job for High Seas; shafts out and checked in our on-site machine shop Straight Line Marine, replace cutlass bearings, service the Kobelco Eagle seals (as mentioned in a prior post) and an Optical Scope Alignment check of all bearings and transmission locations. Both transmissions required a minor alignment to square up to the shaft line.

With remote ZF transmissions the process requires removing the Centax L flexible couplings and adjusting the ZF mounts. This particular vessel had adjustable mounts which is easier than the typical hard-mounted, chockfast arrangement.

Once the ZF transmission was aligned the engines required an alignment to be within Centa’s specifications for the flexible couplings.

Once everything is aligned the Centa couplings are reinstall paying strict attention to the manufacturer’s torque specification. It is also important to install the “Links” (left part of the picture above) in the proper direction given the engine rotation.

One of our good customer’s lost a prop blade while underway in the Caribbean last winter. The angle of the picture is a bit deceiving – approximately 50% of the blade was gone from this 40″ 5-bladed Rolla prop.

The Captain reported running at low speed in relatively calm conditions in clear water when suddently there was a bang and horrible vibration. No sign of hitting anything. There was no damage to the other four blades – no “sanding” of the Prop Speed anti-fouling paint indicating a light bottom touch. It is hard to imagine a single prop blade hitting a floating object at speed without nicking one of the other blades.

This prop had markings from as many as three other prop shops indicating a fair amount of work had been done to these props. The vessel owner and crew are fairly new to the boat so there is no history on past events.

Click to watch the video of a day at High Seas Yacht Service.

Click to watch the video of a day at High Seas Yacht Service. Click to watch Marine Industries Association of South Florida video featuring Salty Jobs at High Seas Services.

Click to watch Marine Industries Association of South Florida video featuring Salty Jobs at High Seas Services.