- 111′ Inace Heading for the Water

We recently wrapped up a few months of work on this 111′ Inace. She required a full engine alignment – moving the front mounts as much as an inch. In addition, the exit tube bearings were out and required a float alignment to get everything in order. This project was complicated by the presence of a Vulcan spool and vibration dampener that required some servicing and spare parts from Italy. Our on-site machine shop handled the Vulcan rebuild to ensure that all of the tolerances were within specification. If you are a few thousandths of an inch off on a 500 pound spool you will get a lot of unnecessary movement in the running gear.

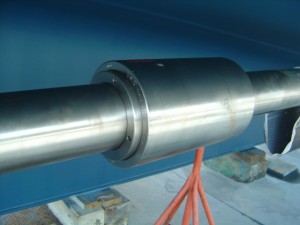

A finished shrink sleeve on an SKF Hydraulic Coupler

- SKF Steel Muff Couplers need to be sealed from sea water with shrink sleeves

SKF OKC Hydraulic Muff Couplers come in steel and stainless steel versions. The majority that we come across are steel even though they are submersed in salt water. Older installations attempted to keep the water out by wrapping the coupler in fiberglass.

SKF Hydraulic Muff Coupler on 5.5" Shaft

Over the past few weeks we have had the pleasure of working on a classic 131′ Feadship. This yacht has 5.5″, three-section shafts with two sets of hydraulic muff couplers (four total). The hydraulic muff coupler manufactured by SKF can be incredibly simple if everything goes well. Removing or installing a hydraulic coupler requires two different hydraulic pumps – one high pressure and one low pressure. The high pressure pump is unique – up to 40,000 psi which requires special high pressure fittings and a great deal of safety precautions. High Seas has the right tools for this job.

The hydraulic coupler installation requires an exact fit and a light touch between the steel coupler sleeve and the shaft ends. There are no fasteners in this system – no bolts, no keys or key-ways. Approximately 7″ of shaft ends that are inside the coupler must be machined to within tenths of a millimeter to the coupler sleeve. This particular sleeve was manufactured to 139.7mm (not 140mm) to give you an idea of the tolerances. No burs or other imperfections are allowed. Mistakes during installation can result in small burs that will destroy the coupler when the next yard tries to remove it.

Our thanks to Steve at SKF for his outstanding customer support. Steve coordinated the expediting of SKF parts for this project and was a wealth of knowledge on a few technical questions. While we have experience working with hydraulic couplers we are also always open to speaking to the company experts to make sure we are taking advantage of all the tricks and knowledge in highly unique parts.

Hydraulic Muff Coupler - the long view

Sometimes you need to be Tall

- Sometimes you need to get low

Aquadrive Anti-Vibration Installation

The entire High Seas team is proud of it’s selection by Mack Boring to be the Aquadrive Service Center for South Florida. Aquadrive systems are popular solutions for boat manufacturers for the elimination of engine and shaft vibration. Aquadrive systems consist of a thrust bearing and a CV “jack shaft” connection between the motor and shaft. High Seas was selected as the service center based on excellent customer service, trained personnel and the dedication to running gear solutions. Aligning Aquadrives must be done properly to keep the V and Thrust bearing temperatures low and extend the service life.

Classic '84 Palmer Johnson with a fresh alignment tune-up

This classic 1984, 84′ Palmer Johnson suffered from binding cutlass bearings. This created vibrations and unusual engine loads. Once hauled, the problem was apparent when it took full body weight leaning on the props to get the shafts to budge. Once the shafts were removed, which was needed for cutlass bearing replacement anyway, the optical scope was set up on each side. The problem was obvious, the bearings in both the intermediate and main struts were out of alignment – a lot. One of the benefits of the optical scope is the ability to show the Captain and Engineer exactly what is wrong.

All four bearings were “float aligned” into the proper, permanent alignment positions. The boat was assembled and launched right on schedule and sea trialed shortly after and headed for its annual 2,000 mile summer delivery. Even before the launch and sea trial the results were apparent – you could now turn the propeller with a single hand. With a good pull you could spin the prop a half turn – pretty nice for gear this size.

It is always great to hear from customers. Three weeks after the work was complete, the PJ was back up North. The Captain called to report the smoothest ride he has felt on the boat in 10 years. In addition, there was a noticeable and substantial savings in fuel. Stay tuned. as we might have some hard data to report in a future update.

I ran across this April 1998 published article and after a quick read realized that things haven’t change that much over time. This article is a great primer for the boater with a mid size yacht that has unfortunately “bumped” bottom. High Seas Yacht Service founder Don Waksman was quoted for his alignment expertise back then.

While the concepts are all the same, the technology is advancing. Back then the optical scope alignment was relatively new. Now it is common place for our company and used every time we pull out shafts. Just straightening shafts is not good enough. Maintaining a proper alignment is critical for a smooth ride, lower maintenance costs, better fuel consumption and overall greater enjoyment of your boat.

- Chris (machinist) lapping props on shaft while turning in the shop lathe.

Power lapping propellers and couplers onto shafts is a real “must” for a high performance alignment and vibration-free installation. Our machine shop always laps props and couplers. The propeller shaft is loaded into the lathe and the propeller is support by an overhead hoist. A lapping compound is spread onto the shaft taper and while the shaft spins in the lathe the prop is repeatedly pressed onto the taper. The lapping compound acts to grind the prop hub and shaft taper until there is a perfect fit between the two.

Strut on ground. Cleaning out the pocket to prepare for reinstallation.

A few weeks ago we started working on a 90′ yacht that had experienced vibration problems at speed. The boat was hauled and shafts removed in order to check the alignment and shaft straightness. During our optical scope analysis it became very clear that both port and starboard struts were out of alignment. This could have been an original factory problem but more likely is a result of careless piloting/navigation by the prior yacht owner. Aligning struts in a yacht this size requires specific tools, techniques and skills. Pulling a 300+ pound strut off a boat can be dangerous – it usually requires significant “coaxing” to break the factory bedding. Getting the same strut back into an alignment position, hanging six feet off the ground, can also be tricky. A quick technical article here will give you more insight to the process. Aligning a strut is usually a once-in-a-boat-life project provided you keep an eye on the charts and keep her off the bottom.

Hundested Prop

As mentioned in an earlier post, we are helping a customer that recently purchased a Custom Steel Boats 65′ Molokia Straights. This “expedition” style yacht had a 38 inch diameter variable pitch propeller system by Hundested. The system uses a 100mm hollow shaft with an inner shaft for hydraulically adjusting pitch while underway – not your common prop & shaft assembly. Our customer is looking to put a lot of sea miles on his new boat and wanted the system completely torn down, inspected and reassembled.

During the project we found we could improve on the shaft bearing system (see May 3rd post on Custom Bearings). We also found, based on scoping, the transmission to be out of alignment by over 1/4″ – a real problem with a shaft that is only 5 feet long.

Special thanks to Steve McGowan, President of McGowan Marine Inc – the US agent for Hundested Propeller, for his support and oversight during this complex project.

Click to watch the video of a day at High Seas Yacht Service.

Click to watch the video of a day at High Seas Yacht Service. Click to watch Marine Industries Association of South Florida video featuring Salty Jobs at High Seas Services.

Click to watch Marine Industries Association of South Florida video featuring Salty Jobs at High Seas Services.